PRODUCT CATALOG

- Air-cooled Electric Vibration Shaker Testing Machine

- Water-cooled Electric Vibration Sharker Testing System

- Inductive Electric Vibration Table Testing System

- Vertical Extension Table for Vibration Testing Equipment

- Horizontal Slide for Vibration Testing Equipment

- Triaxial Vibration Test System

- Six-degree of Freedom Electrodynamic Vibration Testing System

- Electric Ejection Arrester Test Bench for Shock Vibration Testing

- Smart Power Amplifier for Vibration Test Table

- Pneumatic Vertical Shock/Crash Vibration Test Bench System

- Hydraulic Vertical Impact Vibration Test Bench Equipment

- Pneumatic Two-way Vertical Impact Test Bench for Shaker Testing

- Steady-state Acceleration Vibration Testing Bench Machine

- Hydraulic Vibration Test Bench for Hydraulic Vibration Shaker Testing

- Hydraulic Tilt and Swing Vibration Test Bench Equipment

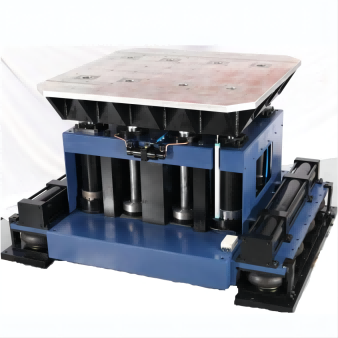

Your Location : Home >> Product Center / Pneumatic Two-way Vertical Impact Test Bench for Shaker Testing / FJ-SKT100 High Performance Shock Test System For Product / Package Shock Testing

| Name | FJ-SKT100 High Performance Shock Test System For Product / Package Shock Testing |

| Place of Origin: | China |

| Brand Name: | FUJIVIBRATION |

| Certification: | ISO,CE |

| Model Number: | FJ-SKT100 |

| Minimum Order Quantity: | 1 set |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Packaging Details: | International standard plywood case |

Product Description

FJ-SKT100 High Performance Shock Test System For Product / Package Shock Testing

| Table Size: | 70 X 80 Cm | Max. Specimen Weight: | 100 Kg |

|---|---|---|---|

| Max. Acceleration: | Half Sine: 600G | Shock Pulse Duration: | 1-30ms |

| Machine Weight: | 3200 Kg | Power Supply: | 3 Phase AC 380V 50/60Hz |

| Name: | Shock Test System With Long Duration Half Sine Shock For Product & Package Shock Testing |

Shock Test System With Long Duration Half Sine Shock for Product & Package Shock Testing

Shock occurs during transit ,delivery ,and in use

Deliverying a qulity product to your cusomters demands knowledge of prodcut ruggedness.

Smaller and lighter weight products are handled more severely and must endure a higher shock environment than previous generation equipment

Selection of High Performance Shock Test System.

We ultimately recommend the most suitable system configuration for every testing application based on two important criteria:

The specimen max. size

The specimen max. weight

The performance capability needed to meet your testing needs

Test Item Size

Each customer has unique requirements for their dynamic testing equipment. It is important to know the size and weight of test items to correctly configure the appropriate testing equipment. The size of your largest test item will help determine the table surface area. The maximum payload will help determine the shock system performance category.

Performance Capability

Shock testing levels vary significantly depending on the product you are evaluating or the conditions you are simulating. The two most important shock performance criteria are velocity change and acceleration level. It is also important to know the shock pulse waveforms—half sine, sawtooth, or trapezoidal.

Product description

Shock testing systems Design standards: GB/T2423-2008, GJB1217, GJB360.23, GJB150, GJB548, MIL-STD-202F, IEC-68-2-27, MIL-STD-883E, MIL-STD-810F, ISTA, UL

Shock testing systems Specifications

| Model | FJ-SKT30 | FJ-SKT50 | FJ-SKT100 | FJ-SKT200 | FJ-SKT300 | FJ-SKT600 | FJ-SKT1000 | |

| Table size (cm) | 40*40 | 50*60 | 70*80 | 100*100 | 120*120 | 150*150 | 200*200 | |

| Maximum Specimen Weight(Kg) | 30 | 50 | 100 | 200 | 300 | 600 | 1000 | |

| Max acceleration(G) | half sine | 600 | 600 | 600 | 500 | 500 | 300 | 300 |

| saw-tooth waveform | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| square | 150 | 150 | 150 | 150 | 100 | 100 | 100 | |

| Pulse Duration (ms) | half sine | 40—0.2 | 40~1 | 40~1 | 30~2 | 20~3 | 20~3 | 20~3 |

| saw-tooth waveform | 18~6 | 18~6 | 18~6 | 18~6 | 18~6 | 18~6 | 18~6 | |

| square | 30~6 | 30~6 | 30~6 | 30~6 | 30~6 | 30~6 | ||

| Machine Dimension(cm) | 120*110*245 | 130*140*260 | 130*120*260 | 150*130*260 | 200*160*300 | 230*180*310 | 250*220*310 | |

| Controller cabinet Dimension(cm) | W55*D50*H80 | |||||||

| Machine Weight(Kg) | 1900 | 2300 | 3200 | 4200 | 8500 | 15500 | 19500 | |

| Utility | 3-phase AC380V 50/60Hz 0.5~0.8MPa | |||||||

| Requirements | ||||||||

| Conforming standards | GB/T2423-2008 GJB1217 GJB360.23 GJB150 GJB548 MIL-STD-202F IEC-68-2-27 MIL-STD-883E MIL-STD-810F ISTA UL | |||||||

German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian Indonesian

Indonesian Vietnamese

Vietnamese