PRODUCT CATALOG

- Air-cooled Electric Vibration Shaker Testing Machine

- Water-cooled Electric Vibration Sharker Testing System

- Inductive Electric Vibration Table Testing System

- Vertical Extension Table for Vibration Testing Equipment

- Horizontal Slide for Vibration Testing Equipment

- Triaxial Vibration Test System

- Six-degree of Freedom Electrodynamic Vibration Testing System

- Electric Ejection Arrester Test Bench for Shock Vibration Testing

- Smart Power Amplifier for Vibration Test Table

- Pneumatic Vertical Shock/Crash Vibration Test Bench System

- Hydraulic Vertical Impact Vibration Test Bench Equipment

- Pneumatic Two-way Vertical Impact Test Bench for Shaker Testing

- Steady-state Acceleration Vibration Testing Bench Machine

- Hydraulic Vibration Test Bench for Hydraulic Vibration Shaker Testing

- Hydraulic Tilt and Swing Vibration Test Bench Equipment

Your Location : Home >> Product Center / Pneumatic Two-way Vertical Impact Test Bench for Shaker Testing / FJ-208 Vibration Testing Motor-driven Machine according to "Junker"

| Name | FJ-208 Vibration Testing Motor-driven Machine according to "Junker" |

| Place of Origin: | China |

| Brand Name: | FUJIVIBRATION |

| Certification: | ISO,CE |

| Model Number: | FJ-208 |

| Minimum Order Quantity: | 1 set |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Packaging Details: | International standard plywood case |

Product Description

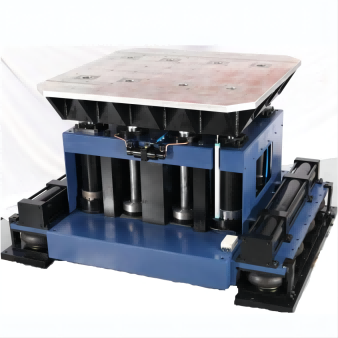

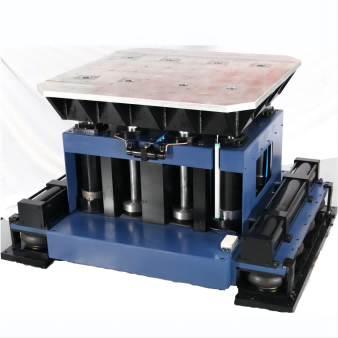

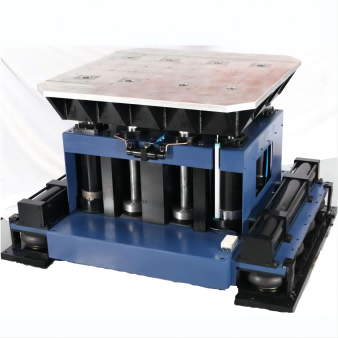

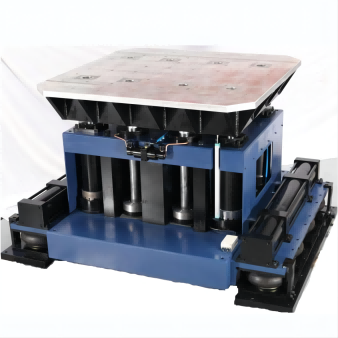

FJ-208 Vibration Testing Motor-driven Machine according to "Junker"

CHARACTERISTICS

Test type: fatigue, durability, vibration, endurance

Operating mode: motorized

Test material: for high-strength bolts, for bolted connections

Sector: for research and development, industrial, for quality control, for the construction industry, for the energy sector, for railway applications

Technology: electromechanical, mechanical, dynamic

DESCRIPTION

To execute a vibration testing procedure according to "Junker" the components to be tested will be screwed into the machine under a defined pre-load. Within the actual testing process they will be exposed to dynamic radial loads, with constant or variable frequencies. The (pre-load) force-time-diagram, which is measured on this way, provides the respective information about the loosening behaviour of the screwed connections. In connection with TesTWinner® you will receive optimum efficiency and flexibility as well as a direct information about loosening angles, pre-load force, transverse-force and transverse-path amplitudes. Features - Motor-driven - TesTController - TesTWinner® - Dynamic - Fastener & Fixing - Automotive Technical specifications Machine Type - Vibration Testing Machine according to "Junker" Application Area - Bolts from M5 up to M42 Detailled Data - See brochure and according to customer's requirement

German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian Indonesian

Indonesian Vietnamese

Vietnamese